Low-Tech Biochar in 2025: Simple kilns, bigger tailwinds, real opportunities

- Dnyaneshwar Pawar

- Aug 14, 2025

- 3 min read

Biochar made from crop residues in low-oxygen conditions—has gone from niche to necessary. What’s changed lately? Three big things: India’s emerging carbon market rules, credible demand for biochar-based carbon removal, and better guidance for clean, low-tech production that smallholders can actually use. ICAP Carbon ActionReuters

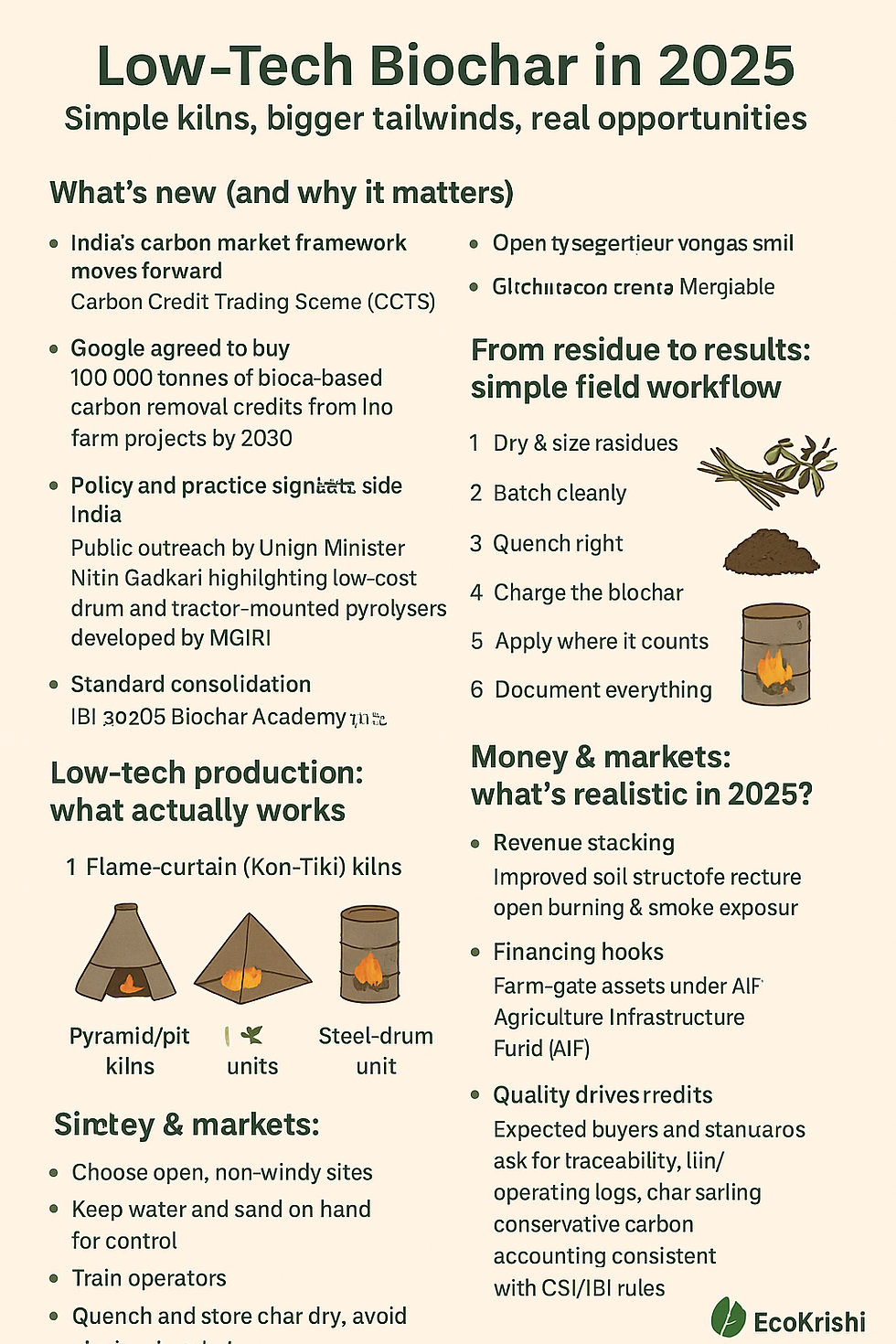

What’s new (and why it matters)

India’s carbon market framework moved forward. In July 2024, India adopted regulations for its planned compliance carbon market under the Carbon Credit Trading Scheme (CCTS)—a structural signal that carbon projects, including biochar, are getting a clearer pathway. ICAP Carbon Action

Major buyers are stepping in. In January 2025, Google agreed to buy 100,000 tonnes of biochar-based carbon removal credits from Indian farm projects run by Varaha, to be delivered by 2030—evidence that high-quality, farm-scale biochar is investable. ReutersIntelliNews

Policy & practice signals inside India. Public outreach by Union Minister Nitin Gadkari has highlighted low-cost drum and tractor-mounted pyrolysers developed by MGIRI (quoted costs in the ₹5,000–₹30,000 range), urging farmers to adopt biochar for soil and income gains. The Times of India

Standards are consolidating. The International Biochar Initiative (IBI) and Carbon Standards International (CSI) announced a standards partnership/merger path—bringing material standards (IBI) together with project certificates (CSI’s World Biochar Certificate), which should simplify compliance for producers. International Biochar InitiativeBioenergy International

Digital MRV is maturing. CSI maintains the Global Artisan C-Sink program for lower-cost, smallholder-friendly biochar projects and publishes a list/process for endorsed digital MRV providers, making documentation more accessible.

Skills & training are scaling. IBI’s 2025 Biochar Academy (India) (Oct 2–10, Hyderabad area) is another sign of momentum for hands-on learning. International Biochar Initiative

Low-tech production: what actually works

You don’t need an industrial reactor to make climate-grade biochar. Three proven “appropriate-tech” options:

Flame-curtain (Kon-Tiki) kilns A conical metal or pit kiln where you add thin layers of dry biomass; the visible flame “cap” consumes smoke and tars, yielding cleaner char with good yields. The Ithaka Institute’s open guidance helped popularize this method. ithaka-institut.org+1ithaka-institut.org+1

Pyramid/pit kilns Sheet-metal pyramids or earth pits are quick to build with local tools. They follow similar “thin-layer, bright-flame, quick-quench” principles and can process mixed residues on-farm. (General method notes align with Kon-Tiki practice.) ithaka-institut.org

Steel-drum units Ultra-low-cost, small-batch systems (including MGIRI designs) are good for demonstrations and micro-plots, and they lower the barrier for first-time users. The Times of India

Clean operation

Recent measurements find that well-run flame-curtain kilns can keep gas/aerosol emissions relatively low compared with many traditional low-cost methods—if you manage moisture and feed rate. In practice: dry feedstock (target <20% moisture), small/frequent charges, keep a steady bright flame, and avoid over-firing to ash. MDPI+1MDPI+1

Join EcoKrishi's Training programme or connect for consultancy services to know more in detail.

Money & markets: what’s realistic in 2025?

Revenue stacking. Farmers and FPOs can capture value from (a) improved soil structure and water retention, (b) reduced open burning and smoke exposure, and (c) potential carbon credits where projects meet standards and MRV. The CCTS rules and global buyer interest (e.g., Google–Varaha) show credible demand if quality is proven. ICAP Carbon ActionReuters

Financing hooks. While “biochar” isn’t always named line-by-line in Indian schemes, farm-gate assets (sheds, handling, basic equipment) can sometimes be supported under the Agriculture Infrastructure Fund (AIF)—worth exploring with local banks/DAOs using the 2024 revised guidelines. agriinfra.dac.gov.in

Quality drives credits. Expect buyers and standards to ask for feedstock traceability, kiln/operating logs, char sampling, and conservative carbon accounting consistent with CSI/IBI rules. Start with good records from day one. International Biochar Initiativecarbon-standards.com

Safety & stewardship

Choose open, non-windy sites away from dry grasses/buildings.

Keep water and sand on hand for control.

Train operators; avoid plastics/treated wood.

Quench and store char dry; dust masks help during crushing/handling. (Best-practice guidance echoes Kon-Tiki documentation.) ithaka-institut.org

The bigger picture

Biochar isn’t a silver bullet, but as part of better residue management and soil health programs, low-tech production offers a rare win-win: less smoke and waste, more resilient soils, and a route to measurable, tradable climate benefits. With standards consolidating and India’s market architecture advancing, 2025 is a pragmatic time to start—or to scale thoughtfully. ICAP Carbon ActionInternational Biochar Initiative

References & further reading

India adopts regulations for planned compliance carbon market under CCTS (July 2024), ICAP. ICAP Carbon Action

Google to buy 100,000 t of India biochar CDR credits from Varaha by 2030, Reuters; context from bne IntelliNews. ReutersIntelliNews

Ministerial outreach on low-cost pyrolysers (MGIRI drum/box units), Times of India. The Times of India

IBI–CSI standards partnership / WBC alignment. International Biochar InitiativeBioenergy International

Practical Kon-Tiki guidance (Ithaka Institute). ithaka-institut.org+1ithaka-institut.org+1

Emission factors for flame-curtain kilns (open-access MDPI article & review notes). MDPI+1MDPI+1

AIF Revised Scheme Guidelines (Sept 2024). agriinfra.dac.gov.in

Training signal: IBI Biochar Academy—India (Oct 2–10, 2025). International Biochar Initiative

Publisher: EcoKrishi

Comments